Standard recycled product range

REPRO

Standard selection of plastic compounds based on high-quality recycled raw material.

Quick and easy supply

The materials in our standard REPRO series are always in stock – convenient for anyone who frequently needs ready availability of compounds based on up to 100% recycled plastic material. REPRO is not designed for one specific segment, but is suitable for many. The product range is designed for automated injection molding processes, and is popular among customers for testing recycled materials in their products.

-

Stock item with flexible delivery times

-

Cost-effective, recycled materials

-

Possible to order large volumes over time

-

High-quality material

-

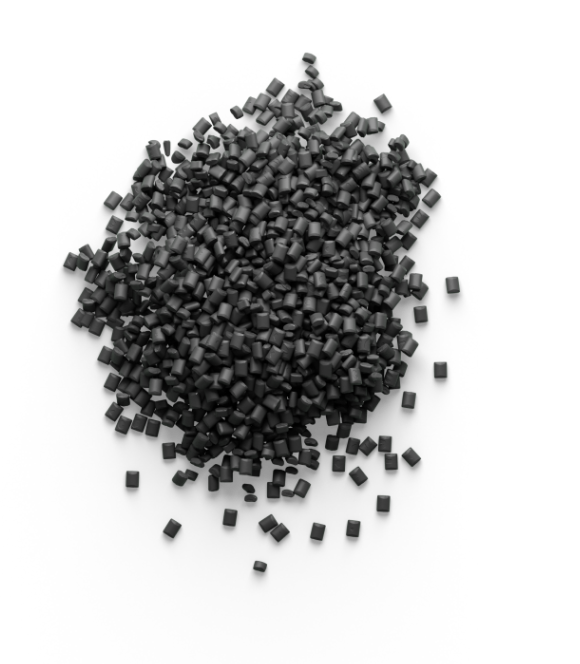

Supplied in black as standard

Complete standard product range

REPRO consists of a wide range of plastic compounds for injection molding and extrusion. Based on PP, ABS, PA6, PA66 and PC/ABS, customers get high-quality recycled material regardless of the base polymer. The materials in REPRO are always black.

How we ensure availability

Greater material access

Reliable sources are hard to find. So, we’re always seeking contacts with new potential suppliers and constantly investing to manage a broad range of sources.

We create a stable supply of recycled materials by processing a wide range of raw materials, from non-wovens to fibers and plastic dust. These constant efforts boost our capacity and help us ensure a sustainable supply of materials for our customers.

Category Manager - Recycled Materials

Patrik Lindqvist

+46 411 797 82

patrik.lindqvist@rondoplast.se

Carbon footprint certificate

If you wish, we can deliver our REPRO materials with a certificate accurately showing the material’s total CO₂ footprint up until it passes through our factory gates. Customers receive traceable materials and figures that are easy to include in their product’s life cycle. The certificate is based on our LCA, which has been approved by a third party.

Sustainability Specialist & Technical Support

Order a sample

Samples of our REPRO materials are available for customers who have not previously used them. Customers are provided with a small amount of material to test and evaluate in their own tools.

Short facs on REPRO stock materials

MFI

Charpy

Filler

E-modulus

* Mixed color

** Medium Viscosity

Personal materials support

-

Personal contact with technical support.

-

We offer a materials proposal based on the customer’s requirement profile, production process and end product.

-

We can be on site with the customer when it’s time for implementation and evaluation.

Patrik Lindqvist

Johan Svenmo