A resource for the future

About recycled plastic

High-quality recycled plastic material to meet tomorrow’s demands for quality and sustainability.

For the planet

Recycled plastic comes with natural environmental benefits. It has a lower carbon footprint and it reduces the amount of plastic waste when recycled instead of being incinerated. Also, choosing recycled plastic rather than virgin material reduces the need to produce plastic from fossil sources.

The shortcut to your green goals

Recycled plastic material can be an easy way to reduce your carbon footprint naturally while maintaining material quality.

For industry

Recycled plastic offers multiple business benefits – the efficient use of resources, a stable supply of materials, a shortcut to your green goals and meeting standards demanded by authorities and customers. Recycled plastic can boost both your green credentials and your competitiveness.

In industry, recycled plastics are not only used in standard components, but also provide great scope for innovations and advanced technical solutions in the automotive industry, for example.

For the consumer

Recycled plastic provides the consumer with the ability to make sustainable choices without compromising quality or functionality. Recycled plastics are becoming more common in everyday products such as furniture, fashion, packaging and more, enabling consumers to reduce their carbon footprint without compromising function or design.

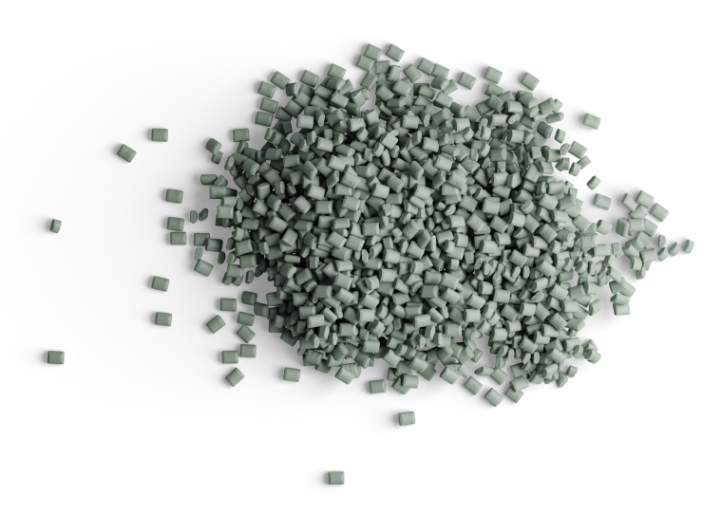

PCR

PCR

There’s a difference between recycled and recycled

PIR

Post industrial recycled

Rejected materials from production, meaning material generated from a production process but which cannot be directly returned for use in the ongoing process.

The material is usually cleaner as it never reaches the consumer level. There is a lower risk of exposure to dirt, coating mixtures or other contamination. Also, there is often greater knowledge about the raw material’s origin and its specific properties. This makes recycling to high quality easier.

PIR is eco-efficient and has a low carbon footprint. This is because PIR has a shorter recycling process, as it reuses relatively clean production waste that would otherwise end up in incineration or landfill. Because the material never reaches the consumer level, it helps make the industry’s own use of resources more efficient.

Because PIR originates from cleaner industrial waste, it provides more even, predictable results. This is an advantage when manufacturing materials in specific colors.

Source

Quality

Environmental impact

Colorability

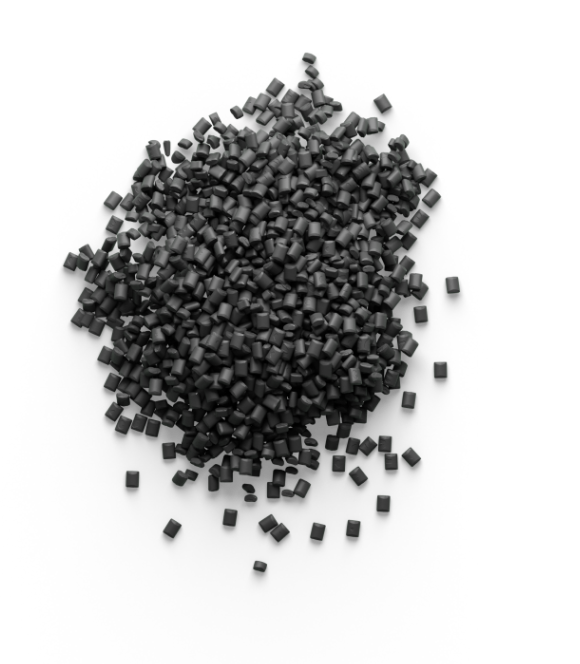

PCR

Post consumer recycled

Plastic material from end-of-life products or packaging used by households or companies.

Although quality may vary due to contaminants and a mixture of materials, technological advances have led to significantly better washing and sorting solutions. These improvements make it possible to produce PCR material of sufficiently high quality for a wide range of applications.

PIR

PIR

PCR

PIR

The material cleaning process requires quantities of water and energy, and this results in a greater climate impact than PIR, but lower than virgin fossil material. The great advantage of PCR is the use it makes of consumer waste that otherwise risks ending up in nature, waste incineration or garbage dumps. We reduce the need for virgin plastic and provide clear support for the circular economy by returning such material to production.

PCR

Raw material that comes from consumer waste is often colored, mixed or discolored by use. This can make it more difficult to color the material in the next step, especially in lighter shades. Thus PCR is often used in darker shades and black.

PIR

Post industrial recyled (PIR) vs. Post consumer recycled (PCR)

Not just any old plastic, but rather quality goods

Sources that safeguard supply

We spend a great deal of time maintaining existing sources of good quality recycled plastic raw material, and establishing collaborations with new sources that meet our quality standards.

Recycled raw materials demand more

Using recycled plastic raw materials as a base demands extensive quality management. Compared with plastics based on virgin material, the production of plastics based on recycled raw material demands more extensive control of sources, more thorough raw material analyses and most importantly, multiple sources to safeguard supply and quality.

Double quality control

We choose our sources carefully and conduct consistent chemical and mechanical analyses of both incoming raw materials and outgoing ready materials. Only materials that meet the required standards enter or leave our factories.

Let us buy your plastic waste

If your production generates plastic waste, you are probably sitting on a valuable resource.

We are constantly establishing new contacts, conducting quality controls and evaluating opportunities for additional sources able to deliver recycled, high-quality plastics.

Contact us if you are interested in selling plastic raw material to us.

Category Manager - Recycled Materials

Patrik Lindqvist

+46 411 797 82

What’s best?

PIR and PCR are both needed for a sustainable industry.

Generally, PIR maintains a higher-quality and is easier to use as a base in recycled plastic materials as it has not been exposed to stress and contamination in the same way as PCR.

From a circular perspective, using PCR is necessary as it returns used plastic to the value chain while also solving many of the problems associated with plastic that ends up in nature.

Mechanical and chemical recycling

Almost all plastic can be recycled

Different items require different recycling methods. The two most common methods are mechanical and chemical recycling. Rondo Plast works mainly with mechanical recycling.

Mechanical plastic recycling

-

Grinds plastic into small pieces that can be melted to form new granulate.

-

Clean, good-quality sources give recycled plastic a performance similar to that of virgin material.

-

A well-established, cost-effective recycling method.

-

Low climate impact.

-

Utilizes the existing colors and reinforcements in the incoming material.

-

Cannot restore lost properties.

Chemical plastic recycling

-

Consists of many different methods for different materials.

-

In some cases, composite materials that are not normally mechanically recyclable can be recycled.

-

A more expensive method, but a good complement to mechanical recycling.

-

Has a greater climate impact than mechanical recycling.

-

Enables fillers, pigments and other impurities to be filtered out, which can provide recycled material with properties similar to those of virgin material.

-

Damaged material can be repaired to some extent.

Rondo Plast’s role in the recycling chain

The life spiral of plastic

Because plastic is a material with almost infinite customization possibilities, it is an invaluable resource for the manufacturing industry. By recycling plastic, we make full use of the resource.

A produced component does not necessarily have to be recycled to form part of the same product again, it can be a valuable resource for a different product instead. We call this the spiral economy.

Virgin plastic begins its life-cycle spiral at our parent company Polykemi.

The compound is moulded into a part or an end product and is sent on for final assembly or directly to the market to provide benefit for as long as possible.

Ideally, products that cannot be recycled are collected and incinerated in district heating installations, to be used as new energy.

We provide new life to end-of-life products by preparing plastic material for reuse as recycled plastic raw material. We either deliver to the customer directly from Rondo Plast or via Polykemi.

We work together with Polykemi, which produces customized compounds based on virgin plastic, high-quality recycled raw material or a mixture of both.

The upgrading process

Four steps to quality materials

While recycled plastics have more to offer, recycling requires a chain of operators, all of whom play a part in the handling of PIR and PCR.

As specialists, we take care of one important step on the road to producing high-quality, born-again plastic material.

1. Collection & sorting

PCR is collected from retail and consumers. The plastic is sorted by polymer type and color.

3. Grinding and compounding

PIR and PCR are ground, melted and customized with reinforcements and additives to form a compound that can be used again, and it is here we make our contribution. We recycle plastic from a wide range of types – fibers, rope, non-wovens, plastic film, labels, dust and shavings.

2. Cleaning

The PCR is washed and pre-treated to remove dirt, labels and unpleasant odors.

4. Manufacturing new products

The compounds are used in the production of automotive components, building materials, white goods, clothing, packaging and more.

Danish UWR chooses Rondo Plast

Recycled PP to meet high stiffness standards

A customized compound based on recycled glass fiber-reinforced PP material was the answer when Denmark’s Urban Water Retention was looking for a material for its modular flood prevention system. The choice of material reduced the product’s CO₂ emissions by around 70 %. The innovation won the prize for Transport and Process & Control in the Aquatech Innovation Awards.

Performance upgraded

Recycled plastic is comparable to virgin material

Does recycled plastic lose quality? Yes, sometimes. But we can upgrade it.

Thorough material analyses allow us to assess the quality of a plastic material and determine which future compounds the raw material may be used in.

We have extensive experience in recycling plastic and customizing materials to meet requirement specifications and end-product applications. By using the appropriate polymers, reinforcements, additives and pigments, we give our compounds the right properties to meet customer requirements. This allows us to produce recycled plastic material whose performance is comparable to compounds based on virgin material.

Part of Polykemi Group, a knowledge-based business

Rondo Plast is part of Polykemi Group – businesses that have been researching, customizing and producing plastic compounds since 1968.

Our shared history and geographical proximity to other production and product development units in the Group means that all Group companies have access to each other’s knowledge, experts and equipment.

Here at Rondo Plast, our integrated knowledge of plastic compound customization is the key to finding the recycled materials that best meet the requirements of our customers.

to light

Recycled for a future in color

From dark

Recycled plastic is always black, right?

Yes, it’s true that we still deliver the majority of recycled plastic materials in black. And also no, it’s perfectly possible to produce recycled plastic compounds in a range of colors ranging from lighter to darker shades given the right conditions.

Our knowledge-based support and close collaboration within the Polykemi Group affords access to many years’ experience and expertise in color matching and technical compounding. Let us help you find the best color and shade option for your compound.

From dark to light