The story of Rondo Plast

Recyclers since 1980

2020

Materialsmart – Truly smart

We launched what is maybe our biggest innovation yet: The Materialsmart® concept. Following a period of thorough work grounded in scientific studies we presented the first version of a concept that helps our customers select materials based on the comparative performance, price and environmental impact of different materials. The purpose of the concept is to make it easier for customers to select a material with a lower carbon footprint and to bring attention to misconceptions about certain materials by using third-party validated data.

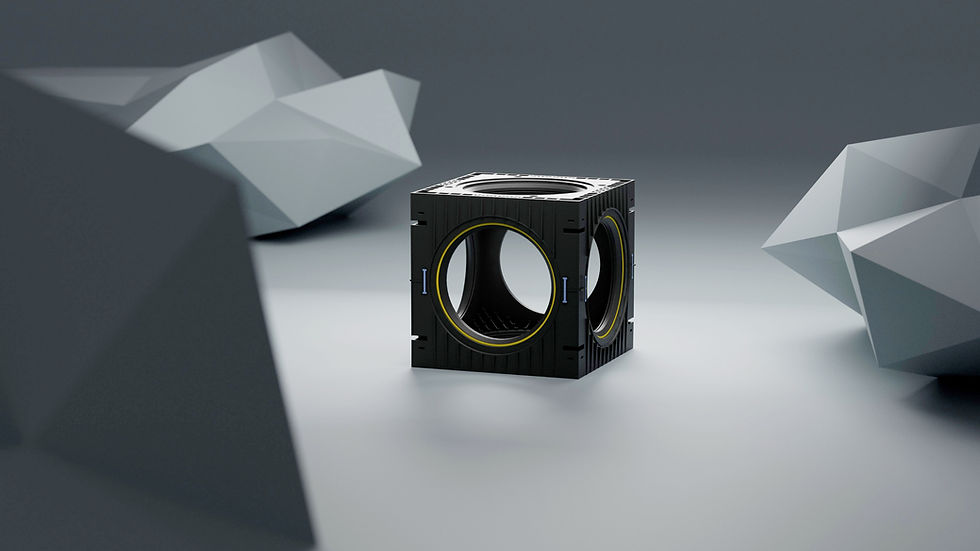

Erema 2024

2024

Increased capacity

The production of recycled plastic material took big steps forward in both volume and quality following major investments in a plastic compactor in 2021, a cutting machine in 2023 and an upgraded Erema in 2024. The greater range of machines and more complex raw materials processing means more potential raw material sources and more potential suppliers, and this has increased our capacity significantly.

2025

Certified

We began work at an early stage to gain ISCC PLUS certification for material based on recycled raw materials, and we were certified in 2025. This means we can provide our customers with a certificate guaranteeing traceability and the amount of recycled mass-balance plastic raw material in the material delivered to them, and this applies to all production from our facilities in Ystad, Sweden.

2004

1980

2012

90'

2018

Pioneers

Rondo Plast was founded as a Polykemi subsidiary on May 1, 1980. The business was founded on an ambition to concentrate on the production of plastic materials based on recycled raw material and to focus production on virgin material at Polykemi. Recycled plastic was not held in high regard during the 1980s – rather the opposite – and so we moved Rondo Plast’s production to an address away from the rest of Polykemi.

Going against the flow

Determined to go against the flow and convinced that recycled plastic material was an untapped resource, we made great headway in the 1990s. Initially we handled mainly polyethylene and polystyrene, but made a gradual transition to become a full-range plastics recycler. Our goal soon involved working to become northern Europe’s most modern recycler of technical plastic materials.

Rondo goes on growing

Our business grew steadily for 20 years, as did the demand for recycled material. We foresaw a future where the demand for recycled material would continue to grow, and so we made plans for new, larger, more suitable premises. We moved into our current premises in 2004.

The breakthrough

The REPRO and REZYcom product groups made a real impact on the market: REPRO, a popular standard portfolio of materials for use in automated injection molding processes, and REZYcom, an application-based solution that makes full use of the Polykemi Group’s experience and expertise in the field of technical compounding.

At least 25% recycled

A Swedish car manufacturer decided that their vehicles should contain at least 25 percent recycled plastic material by 2025, and we were invited to propose materials. A concept vehicle was created based on a great deal of recycled material from us, and the car manufacturer embarked on a world tour. We were invited to talk about our collaboration at the Plastics Recycling and Circular Economy Conference and Showcase in Guangzhou, China.