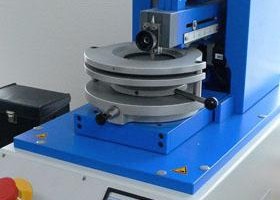

Tensile & flexural tests

The flexural and tensile properties of the material are tested by applying a load to test specimens for a given time period. Such testing provides values such as E-module, flexural stress, tensile stress and elongation.

Läs mer