Nachhaltigkeit ist nicht nur wichtig für die Zukunft von uns, unseren Kindern und den kommenden Generationen, sondern auch ein Schlüssel zum Unternehmenswachstum. Nachhaltigkeit ist eine Frage des Überlebens.

In der Videoreihe „Global Thinkers“- anzusehen auf You Tube (Ländersprache unter „Einstellungen) – lernen wir Organisationen kennen, die am „Ystad-Modell“ beteiligt sind – einem Leitfaden für Unternehmen, um die Geschäftsentwicklung auf der Grundlage der Nachhaltigkeitsziele der UN zu gestalten. Polykemi ist eines der teilnehmenden Unternehmen.

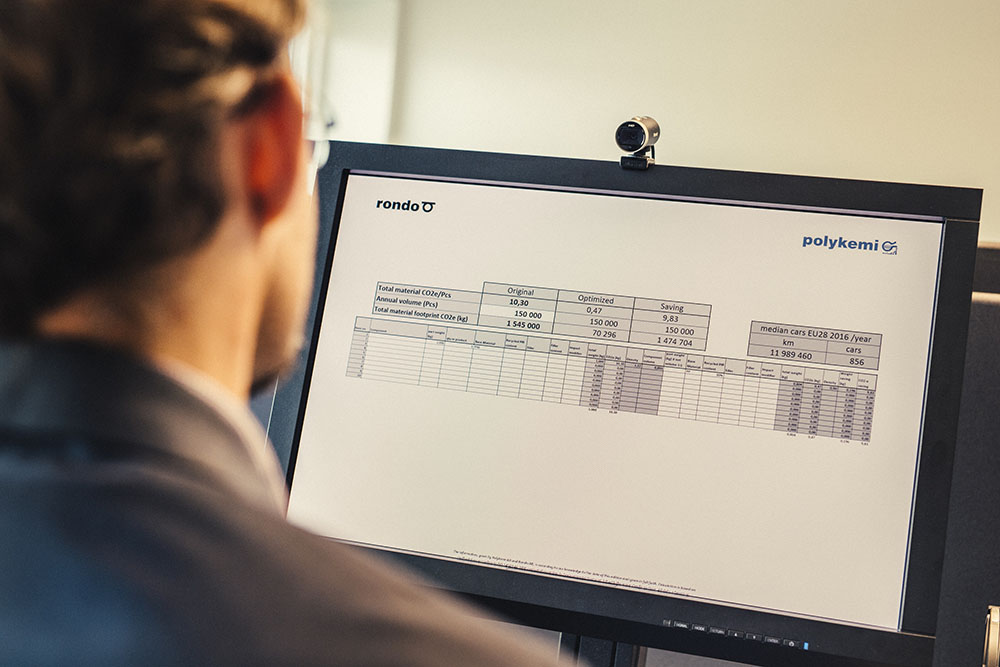

Wir erklären, wie unser Material-Smart-Projekt begann, wie wir vom Lieferanten zum Berater wurden und wie wir unsere Kunden unterstützen, ihren Co2 -Fußabdruck zu reduzieren, indem wir das richtige Material für den richtigen Einsatz vorschlagen.

Das Video ist auf Schwedisch, englische Untertitel sind verfügbar.